ORBITALSERVICE®

Tube-to-tubesheet weld heads

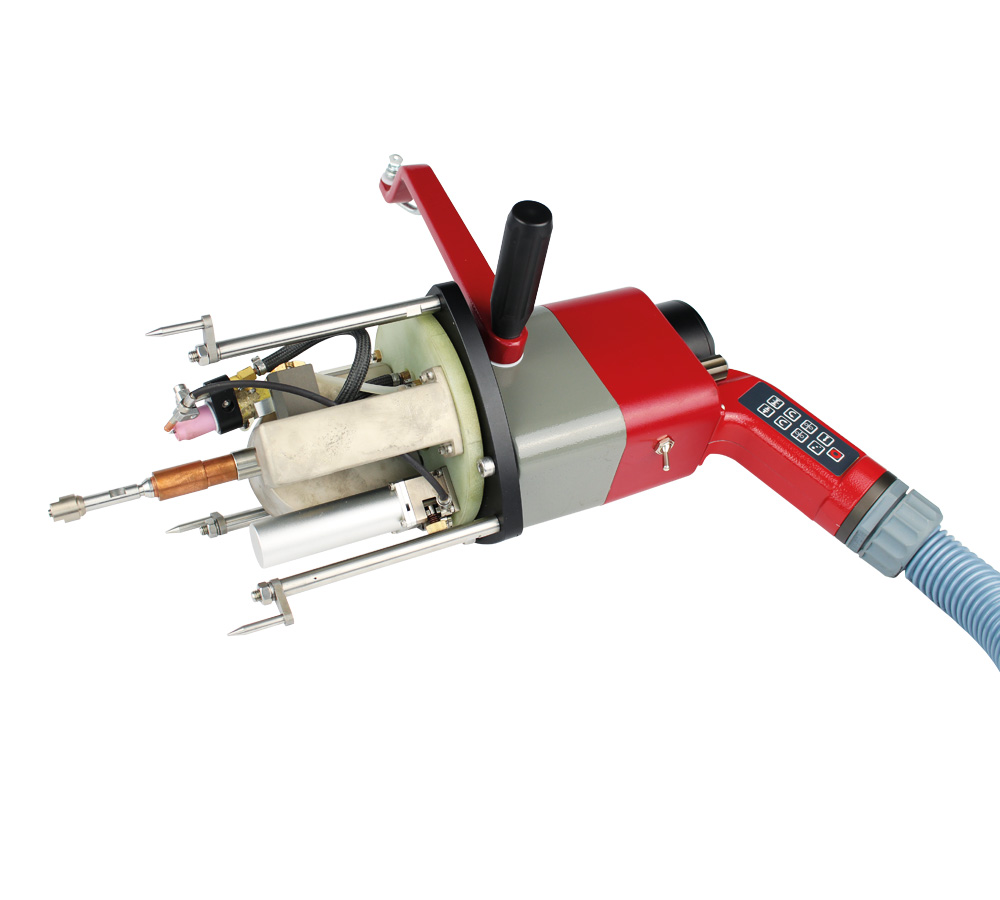

TTS 40, TTS 90, TTS 90 AVC, TTS-Autoline

Suitable welding heads for every project

Here you can find an overview of our range of tube-to-tubesheet weld heads. We would be glad to provide you with further information which weld head is suitable for you.

Whether it is our small, handy and easy operable tube-to-tubesheet weld head without cold wire for stainless steels, titan and nickel-based-alloy, or our tube-to-tubesheet weld head with cold wire feeder (turning) for TIG-DC-weldings.

We have the suitable product for your projects.

Using the additional AVC system, the TTS 90 AVC allows to weld e.g. two layers in just one clamping. In addition, the new head has a button „wire ON / OFF“ as well as „start ON / OFF“ in the handle – vandalism safe. The mechanical travel distance of the burner is 15 mm and the AVC distance plus / minus 5 mm.